News

RE-EXPORT OF SMUGGLED CIGARETTES

RE-EXPORT OF SMUGGLED CIGARETTES

25/10/2016

25/10/2016 Vinataba Saigon Veterans Committee participated in Singing Contest for Veterans in Binh Chanh Dist. 2016

Vinataba Saigon Veterans Committee participated in Singing Contest for Veterans in Binh Chanh Dist. 2016

07/10/2016

07/10/2016 Children of employees honored for good achievements during school year 2015-2016 in commendation ceremony held...

Children of employees honored for good achievements during school year 2015-2016 in commendation ceremony held...

07/10/2016

07/10/2016 Vietnam National Tobacco Corporation: basically completed the restructuring scheme

Vietnam National Tobacco Corporation: basically completed the restructuring scheme

07/10/2016

07/10/2016 “Office Informatics Contest 2016”

“Office Informatics Contest 2016”

06/10/2016

06/10/2016

85-year Journey

Product Development Strategy

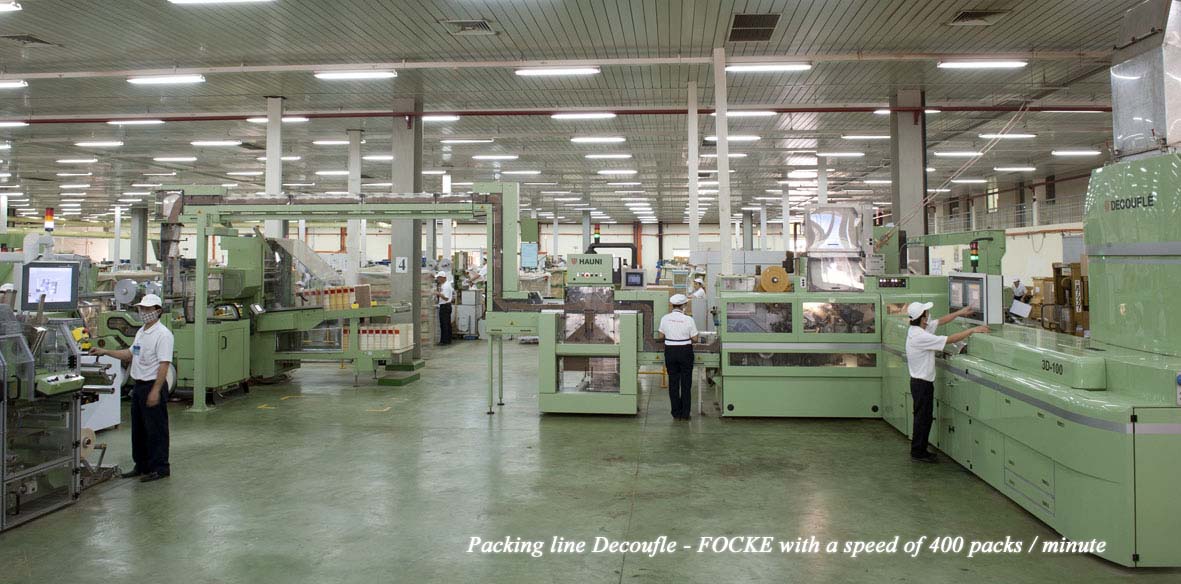

In response to the rapid change of national and international cigarette market towards medium and premium products, our R&D department has continuously presented innovation programs from designs, brandings to product quality. First, we renovate traditional products that have been adopted from consumers for years. We focus on improving product quality to meet specific demands of target consumers. Besides, we pay attention to developing super slim, slim, 10mm tube; charcoal filter, airy filter; international pack, king size, compact, 10 cig pack, round corner pack; Virginia classic blend, Virginia modified, American, American modified… to meet consumer and market demands. These innovative developments have quickly gained reputation in national and international market, including medium and premium targets. Consequently, export values in 3 continuous years 2011, 2012, 2013 increasesignificantly. More specifically, in 2011 export value reaches 71.5 million USD; 2012 encountered a decrease due to global economic crisis, but in 2013 it dramatically jumps to 83.3 million USD.

In the product development strategy, throughout the recent years, the company has always focused on investing in designing packages, refining the outlook; transform the normal paper into wax paper, decreasing the cost in rolling, as well as researching for new materials to lengthen reserving period. This is considered the synergized direction of programs and solutions in the progress of executing product development strategy. Which, incorporating with material quality elevating solution, has positively affected the production of premium lines for exporting and meeting the continuously elevating demand of national market. The short term result of this program has established a new and more modern management methodfor all product lines to strictly obey through the process from choosing creditable suppliers, controlling quality of materials according to ISO standards, to reserving at warehouses totally controlled by technical standards of FIFO.

Along with the incorporation of researching for new products, elevating production management quality and innovating designs to meet market demands, the company pays attention to building trust in its clients. Effects of the program are seen crystal clear through the criteria established and stabilized within such a short time. With modern production line, professional mechanic team, stable product quality… we have gradually established our position and competitive advantage in national and international market. Our products follow the tar and nicotine reduction process of the government, eventually reducing bad effects on consumers, expanding our distribution net, huge production scale, heightening brand creditability and product quality, which all contributing in decreasing cigarette import, especially in big cities like HCMC, Hanoi, Cuu Long delta provinces…

Inevitably, the product development approved by the board, executed with high determination has delivered huge economic benefits not only in the criteria of production, consumption, interest but also and on top are management level, established production technology following trends of the world. Through which, we established our quality, creditability and trust of consumers nationally and internationally in commercially beneficial products. On top of all, as our board of director has a vision that, only activeness, determination and creativity in executing the product development strategy will create competitive advantages in the fierce market at the time being, establishing VINATABA products as the pioneer of Vietnam National Tobacco Corporation.

|

|

|

|

The orientation meeting of Hauni experts on "Optimizing the production process - GPO" |

Research Department - Laboratory |

Other:

- Sharing social responsibility

24/10/2016

24/10/2016 - Expanding export markets for cigarettes

24/10/2016

24/10/2016